With increasing focus on building resilience, builders, engineers and architects are now more than ever expected to deliver a building that is not only visually appealing and meets the design intent, but more importantly, is compliant, more durable, performs as it should, and is better able to resist environmental conditions.

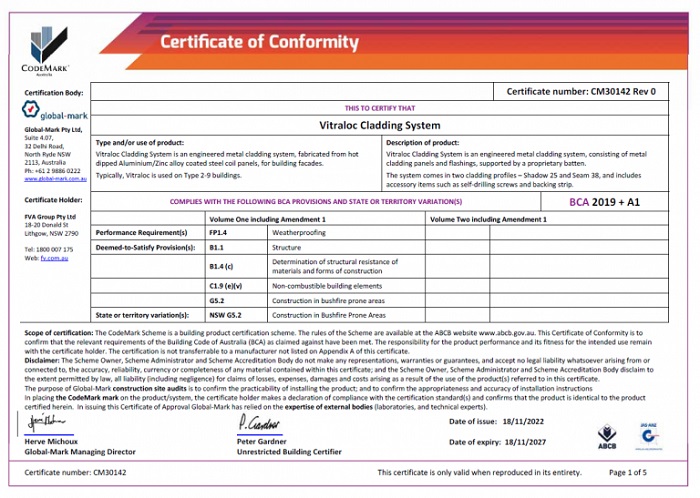

Vitraloc is the first linear panel facade system of its type in Australia to qualify for Codemark certification.

Did you know 85% of multi-owned buildings built since 2000 had defects? And 40% of these were a result of poor waterproofing practices?

Waterproofing equates to just 1% of a building’s costs, yet water defects and the resulting damage can account for 80% of all building defects. The total cost of building defects in Australia was $6.2 billion over the last 10 years and approximately $1.4 billion of that was due to water damage.

These statistics paint a bleak picture – compliant and sufficient weatherproofing is critical in future proofing your design and build, avoiding defects that could otherwise result in loss of both time and money. Furthermore, Professional Indemnity insurance does not cover non-compliant cladding – this includes improper waterproofing.

A weatherproof building provides a safe environment for its occupants and provides a barrier from the effects of weather that can lead to damage and poor health.

AS4284 reporting sets out the test conditions under which a building’s weather tightness can be assessed, which in turn helps manufacturers develop systems that enhance the performance of the facade solution.

Fairview’s Australian Made Vitraloc has been tested in a NATA accredited testing facility. Vitraloc as a system passed the requirements of AS4284, ensuring a weathertight finish for the building and peace of mind for the engineer, architect and asset owner. Take away the gamble and opt for a system that is both tested and known to perform as a complete cladding solution.

Vitraloc – Aesthetic meets performance

Vitraloc architectural steel cladding makes a visually striking and sophisticated design statement with its distinctive tall sharp ribs and flat smooth pan profiles for that bold and modern architectural look.

Made from non-combustible roll-formed steel, Vitraloc provides peace of mind and freedom of expression with an extensive palette of colours and textures. The range of metallics provides a unique finishing option – with lux finishes that are exclusive to Fairview.

Vitraloc is part of Fairview’s extensive architectural product range and shares a unique DNA with the distinctive Stryüm aluminium linear wall cladding system. Fairview has made product selection simple by offering an extensive range of standardised flashings and two profiles options in the 38mm Seam direct-fix panel with a 265mm cover and 25mm Shadow interlocking panels with a 285mm (plus 15mm express joint) cover. The pan width of the two profiles reflects optimum performance and aesthetic proportions. Custom widths are also available on request.

Fully tested as a system for weatherproofing

Leaving little to chance, Vitraloc cladding with its accompanying flashings and accessories, forms part of an engineered and fully tested system.

In addition to its Codemark Certification that confirms the relevant requirements of the Building Code of Australia (BCA) have been met, Vitraloc has been fully tested as a complete system to AS4824. This means the two main profiles – Shadow and Seam – have been tested together with each flashing and connection piece to ensure weathertightness and strength.

When you install Vitraloc – you know each component that is installed on your facade has been designed, tested and installed together as a system rather than just a bunch of components.

What this means is absolute peace of mind. As an architect, engineer or certifier, there is no guesswork, no risk to the designed system’s performance, and no questions whether this system meets the requirements of the building code.

Vitraloc has been developed with over 50 flashing details to maximise flexibility and design options, while also allowing for a weatherproof building regardless of the installation requirements.

The benefit of having readymade flashings is that there’s not only zero need to fabricate flashings onsite, but when used on a project, the total system if installed according to the technical manual, will be Codemark compliant and thus provides peace of mind for all concerned.

When specifying compliant cladding options, common experience is that the existence of an AS4284 test report is sufficient. However, this is not the case. It is important to review the test report and ensure that the detailing and pressures are relevant for each individual project.

Each building will have both a Serviceable Windload Pressure and an Ultimate Windload Pressure, which must be known in order to discover whether a particular product can be used on a specific building.

Fairview cladding products are Australian Standards AS4284 tested for high performance, energy efficiency and minimal maintenance; our products are built for the future. Our test results demonstrate industry leading performance and are readily available for analysis of both Serviceable and Ultimate Windload Pressures.

Vitraloc undertaking AS4284 testing, while utilising the Shadow profile with trims