The acoustic benefits of perforated metal

Did you know perforated metal can be a key component in interior and exterior design for controlling sound?

Here’s how architects and designers are using perforated metal to manage noise:

Perforated metal in acoustics is typically applied as ceiling panels, wall cladding, screening and architectural facade to control sounds and noises within residential, leisure and commercial buildings.

Depending on the acoustic issue, each panel can be designed to help absorb, reflect or scatter sound, or to cut out certain frequencies.

But how does it work?

Using perforated metal to absorb sound

When absorbing, reflecting or scattering sound, perforated metal acts as a protective and acoustically ‘transparent’ covering for acoustic material. As the acoustic material itself is responsible for achieving the necessary noise control, the perforated metal has to be transparent to sound waves, so sound can reach the material behind.

When using perforated metal in acoustics in this way, it’s important to specify a perforation pattern and material that offers the greatest sound transparency for all frequency levels. This is typically a perforation pattern of lots of small holes, closely spaced, to allow maximum sound to pass through.

This type of application can be used in interiors. It’s commonly seen in offices, hotels, stadiums, schools, leisure centres and industrial work environments, when control of ambient sound is needed. Architects may also use perforated metal in this way as exterior cladding to block outdoor sounds.

Using perforated metal to manage frequencies

If you want to cut out or reduce a specific problem noise, perforated metal isn’t required to be transparent but has an active role in acoustic control through a resonant sound absorber.

In this type of application, the holes in the perforated metal panels interact with a layer of trapped air to concentrate the absorbed sounds into a specified frequency range. These types of systems are highly efficient at absorbing low frequency sounds.

Perforation pattern, pitch and thickness of the metal material are crucial to achieve the required result.

Which material is best for using perforated metal in acoustics?

When choosing the material of perforated metal in acoustics, aluminium and stainless steel are the most common metal choices as they retain strength when perforated, even in the thinnest profile.

Advantages of using perforated metal in acoustics

There are multiple benefits to specifying perforated metal for acoustic applications:

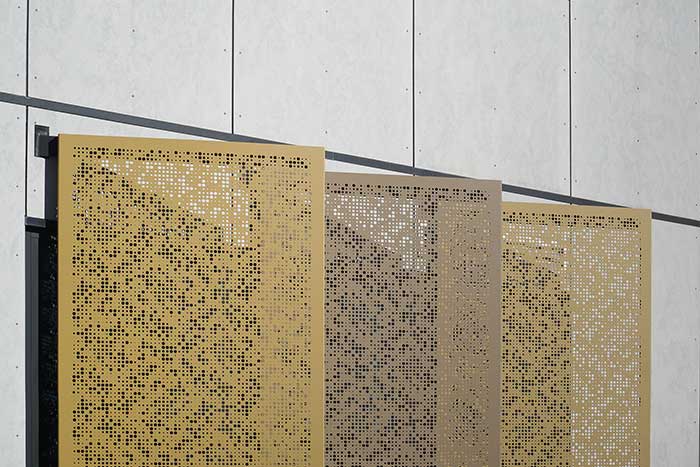

- Perforated metal is a beautiful solution to sound problems as it’s aesthetically appealing in a wide choice of designs and finishes, including powdercoated, coloured or metallic coatings.

- It offers a wide variety of perforation patterns, with many different hole sizes, shapes and pitches.

- Perforated metal panels for acoustic applications – particularly architectural – can be folded, adding further decorative visual interest whilst reflecting or managing noise.

- Perforated metal is durable and easy to maintain, without compromising the function of the acoustic material behind it.

Arrow Metal: Proven metal perforation experts

Arrow Metal has an extensive range of readymade perforated metal panels in stock, ready for immediate dispatch to anywhere in Australia, in a choice of popular hole styles, sizes and materials.