While glue is undoubtedly a marvel of modern engineering, providing unparalleled solutions for joining disparate materials and creating strong, durable bonds, it presents sustainability challenges. The use of glue in building products complicates their end-of-life stage, as it disrupts the homogeneity of materials, making disassembly and recycling more difficult and often resulting in waste. At Autex Acoustics, we recognize these challenges and are committed to finding more sustainable alternatives, continually working towards reducing the environmental impact of our products.

The transformative power of foresight

So it comes as no surprise that at Autex Acoustics, minimizing the use of adhesives and finding alternative installation methods is a core principle in their product design.“Because for us sustainability is non-negotiable, it narrows the design criteria,” shares Jonathan Mountfort, Creative Director at Autex Acoustics.

“It means I can't simply glue materials together or combine mismatched polymers. I really try to consider the future: someone mining a landfill in 50 years shouldn't be cursing at the difficulty of separating components.”

This approach is echoed by Sam Wells, Autex Acoustics' Product Development Lead, who reiterates the company's commitment to creating genuinely circular acoustic products. “Our industry has an issue with waste, and so there is a demand for solutions that find ways to repurpose and recycle the materials we have access to, extending their life and keeping them out of landfills,” he says. "Circularity means considering the entire lifecycle of a product, not just how it will be used in the first instance.”

While such foresight is a fundamental component of creating a more sustainable future, few manufacturers use it as a guiding principle. But then, Autex Acoustics isn’t like other manufacturers – and their latest material innovations and product releases highlight the fact that this holistic, unwavering and deeply inspired approach to sustainability underpins everything they do.

The twists and turns of material innovation

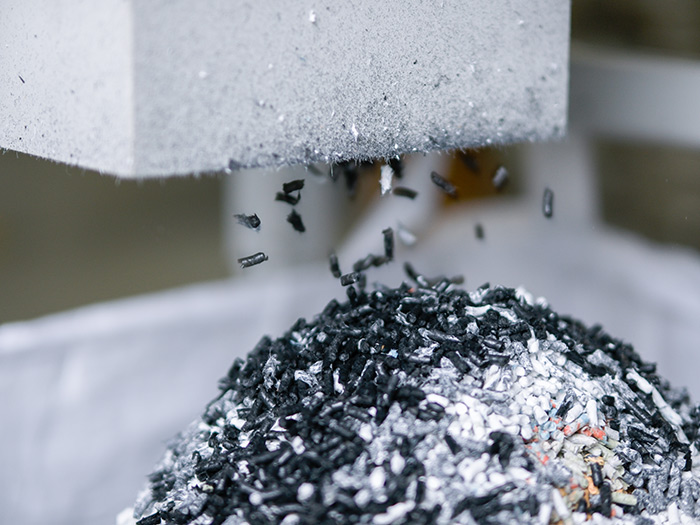

This commitment to circularity is evident in one of Autex Acoustics latest innovations, SpinFix. This ingenious mounting system for acoustic panels uses friction welding instead of glue. They allow panels to be clipped onto a wall without the use of any adhesives – maintaining its single-material form. Now, the ingenuity of this incredible design doesn’t end there – SpinFix is also one of the first products to really showcase the incredible potential of Autex's trailblazing pelletising process.

Three years in the making, this pioneering process transforms manufacturing offcuts from acoustic panels into RePET, a plastic pellet, which is then used as a raw material to produce accessories, like SpinFix. And because SpinFix uses Autex’s friction welding technology to bind the 100% PET SpinFix clips to the panels without the use of glue, everything remains 100% polyester – and that means it can be easily recycled at the end of its life, and become a raw material for the manufacture of a new product.

From circular products to circular systems

This, of course, creates a circular pathway – the pursuit of which is undoubtedly a hallmark of Autex Acoustics design practice. But Autex isn’t necessarily in the business of only designing circular acoustic products. They’re in the business of creating fully circular systems.

“The big focus for us has been on creating something that is truly circular,” says Sam. “As a result, we need to be designing systems that are sustainable and not one-off products. This ensures the materials we create can be repurposed over and over again.”

Sam points out that creating truly circular systems involves more than using recycled materials and producing a recyclable product. Jonathan adds that the brand has been focusing on the development of novel recycling and game-changing material pathways for PET products following their takeback. “The goal is to create products that improve the environment the more they are used,” he explains.

This sentiment – completely reframing the very idea of waste – is reflected in ReForm, a circular product Autex has just launched in New Zealand. The ReForm panels are created from reclaimed textile material, using a combination of PET material from their manufacturing offcuts as well as Autex products at the end of their life, effectively closing the loop.

“The original panel, made from post-consumer acoustics, offers a cost saving compared to the development of a new one, establishing the first loop in a circular material cycle – from fibre to fibre,” Jonathan explains. This fibre-to-fibre process can then be repeated a couple of times, further enhancing the input for the pelletising process and transforming a disposable plastic bottle with a short lifespan into an acoustic panel lasting two decades. And if this panel is repurposed, its lifespan can be extended to several decades, transforming a short-lived product that ends up in landfill into a long-lasting, usable solution. “This process can be repeated potentially even beyond our lifetimes,” Jonathan enthuses.

In Australia, Autex is advancing their circularity efforts by piloting a Takeback Programme for their Acoustic Soffit Liner (ASL) product, a thermal and acoustic soffit and slab liner, with the view of expanding this programme throughout their entire product range. “We are committed to ensuring that the materials collected in our takeback of ASL are repurposed sustainably, with full control over the entire process,” Jonathan explains. “We reintegrate offcuts from production and building sites, as well as end-of-life panels returned from the Takeback Programme, into our own manufacturing processes.”

The future if circular

Glue, in many ways, represents the traditional approach to both manufacturing and construction. It offers an effective solution for right here, and right now, but perhaps lacks the foresight to consider environmental implications down the line. In that regard, Autex Acoustics – and products like SpinFix – represent a change of guard by showing that ingenuity, innovation and sustainability are the principles we should all stick to.

By challenging conventional methods and embracing circularity, they've proven that it's possible to create high-performance acoustic solutions that are not only durable and beautiful but also sustainable and regenerative. Their pioneering approach to material innovation and closed-loop systems sets a new standard for the building industry, showcasing a future where both the built environment and the planet thrive on homogenous, single-material solutions that are infinitely recyclable and reusable – and improve the environment the more they are used.