The notorious vulnerable point in any building’s thermal envelope, giving proper consideration to windows and doors pays dividends in the energy efficiency stakes. That’s one of the fundamentals of a newcomer to the Australian building market, Ichijo Technological Homes.

“It’s pronounced “itchy-Joe”, explains Phil Stewart, managing director for Ichijo in Australia.

An architect himself, after working in Japan, Stewart is using his experience and knowledge to see that the ‘i-Smart’ homes gain a foothold in Australia.

He says the company’s approach makes them unique in world: “They’ve been around in Japan for 35 years, where they build 11,000 homes per year. Over time they’ve refined and developed their own products, so they’re a product development company as much as a builder.

“We’ve taken the best of that technology and created two homes for the Austrlian market, a 7 and 8 star Nathers (Nationwide House Energy Rating Scheme) version.”

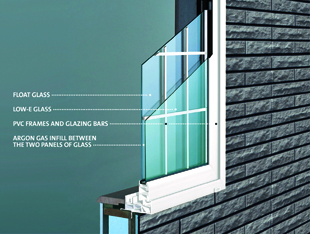

The key ingredients to their concept are the modular panel wall building system, argon gas filled double glazed windows, and the heating, ventilation and air conditioning (HVAC) system.

The key ingredients to their concept are the modular panel wall building system, argon gas filled double glazed windows, and the heating, ventilation and air conditioning (HVAC) system.

While in Australia most of the building products and materials are sourced locally – about 90 per cent, Stewart says - the prefabricated wall panels and windows are imported from the company’s manufacturing facilities in the Philippines, the windows delivered already set into the wall system.

Consisting of seven material layers, the walls are constructed with 70 per cent more structural timber and three times the insulation of standard Australian timber frames. This is said to ensure an insulation R-value three times more efficient than standard brick-veneer.

Vertical-ventilated air-gaps prevent moisture and mould from penetrating the walls and decaying the timber frames.

The combination maximises thermal and acoustic efficiency, and minimises infiltration of dust and pollen.

Countering the air tightness, the HVAC system allows the air to be replaced once every three hours. The system eliminates humidity that causes condensation and mould growth as well as any harmful VOCs. An air filter removes pollens and dusts from the outside air.

i-Smart Windows

i-Smart Windows

The argon gas-filled double glazed uPVC windows, engineered to integrate with the wall system, fit with a perfect seal. This, Stewart says, provides three times the insulation (measured R-Value) of common single-glazed aluminium framed windows, reducing heat loss in the winter by up to 70 per cent and preventing condensation from occurring - preventing health hazards such as mould and mildew.

It means the homes have been recognised with the National Asthmas Council’s Sensitive Choice logo, the first builder in Australia to receive this recognition.

The windows are filled with argon gas between the panes to reduce thermal conductivity. The low-E glass cover allows light in, while cutting the amount of UVR radiation by up to 97 per cent.

In addition, Stewart says perimeter seals, as sourced in Australia, are applied around the non-Ichijo locally supplied doors, to maintain air tightness; for instance, around the front door and any external stackable, sliding or hung door options. Stewart adds they are on the lookout for local door suppliers.

“We’ve worked to get our own products approved and compliant with the AWA (Australian Windows Association). We’re now in the process of working out compliance for Australian bushfire zones,” he says.

“We’ve worked to get our own products approved and compliant with the AWA (Australian Windows Association). We’re now in the process of working out compliance for Australian bushfire zones,” he says.

And while the homes are Greensmart accredited and marketed as healthy, Stewart explains the company is not positioning itself specifically as ‘sustainable’. The real key to the Ichijo venture is price; savings come via globalised economies (hence the company says their price point for an 8-star home is unbeatable) and quicker construction time with prefabricated materials (16 -20 weeks for completion). The other boon is ongoing household energy cost savings.