A typical Australian residential project may require various external surface water drainage systems. These could potentially be installed in the driveway, in front of the garage door, along paths and/or at building entrances. These drainage systems will often be referred to as channel drain, strip drain, trench drain or slot drain. In most cases this terminology is interchangeable and generally means the same thing; however, some manufacturers may use it to highlight subtle differences in their product range.

What is the purpose of driveway drainage?

Driveway drainage can be installed at the garage entrance, the end of the drive or even at a selected point across or down the edge of the drive. The location can be determined by the topography of the section to catch surface water runoff, preventing it from entering or flooding specific areas.

Using drainage systems to prevent safety risks and damage to property

In new developments, sections are often built up on the land with a small fall down the drive to the street. This is designed to direct surface water away from dwellings; however, some local authorities may encourage the capture of surface water runoff from impermeable surfaces (the driveway) so as not to have large volumes of water washing across pavements. Positioning a channel drain along the edge of the property boundary and driveway will capture the water being directed away from the house – collecting and transferring it into the local authority’s stormwater system.

Some sections on hillsides or older suburbs may have the fall in their land directing surface water towards their property. In this case a trench/channel drain can be installed partway down the drive or in front of the garage and house to catch surface water before it enters the property.

Using a channel drain across a garage door entrance

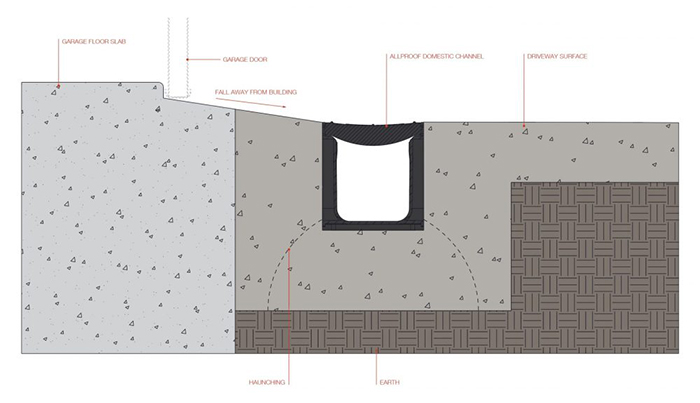

Garage door drain is a channel drain installed across the entire garage door opening to catch surface water, preventing it from entering the garage. For the practical use of a garage space a level entry is required, allowing vehicles or equipment to enter and exit the garage. Therefore, a channel drain is needed across the entrance. It is advisable to implement a small change between the internal floor level of the garage and external surface. A small ramp into the garage that would still allow a vehicle access will also direct rainwater and surface water away from the opening. The channel itself will be installed into the external driveway surface. For load rating requirements mentioned below, a full concrete surround is needed, so pulling the drainage channel away from the floor slab of the garage allows for this and provides room for the ramp to be installed.

Selecting the right drainage grate and channel drain

Different grate designs provide different attributes, some of which are covered further down, but a key feature is the grate’s hydraulic performance. The grate’s open area will play a major role in its ability to efficiently remove surface water. Some grates such as the architectural wedge wire provide a larger total open area; however, the individual openings are smaller in size. Grates with larger openings are less likely to become blocked with debris such as dirt and leaves but may also present issues for items such as bicycle tyres or things you don’t wish to go down (e.g., dropped keys). For grates such as the wedge wire, a regular maintenance schedule could be needed to ensure the drainage grate works effectively if desired for its other features of aesthetic appeal.

Allproof supplies a slot drain grate, which connects to a channel below. The slot drain is a narrow and continuous 15mm opening creating a discreet drainage solution. This is ideal for large flat surfaces such as courtyards, paved areas, around a pool or alongside a raised planter bed or wall. However, if installed at the bottom of a steep surface such as a drive, the narrow opening can be hydraulically bridged by fast flowing surface water. A wider traditional channel drain would catch more surface water, preventing it from entering the area on the other side of the channel.

Channels come in a range of widths and depths allowing for a higher flow rate and better hydraulic performance. Additionally, the location of the outlet can improve the flow rate; a vertical outlet in the bottom of the channel can provide a higher flow rate and hydraulic performance than a horizontal outlet at the end of the channel. Further to that, increasing the number of outlets in the channel can improve its efficiency.

Long-lasting driveway drain

Remedial work can be costly, as is over engineering, so selecting the correct system from the start will ensure a long-lasting and economic solution. It is important to consider the use of the drive; for instance, will the drainage channel be subjected to heavy loads such as large vehicles or boats? If so, selecting a driveway drain with a load class rating of C (AS3996), which caters to light commercial vehicles would provide a robust and long-lasting solution. Will heavy vehicles be turning into the drive? Dynamic wheel loads can move drainage grates, knocking them against the side of the channel and potentially cracking the surrounding concrete. If this is a likely scenario, selecting a system that incorporates lockdowns such as polymer concrete will prevent grate movement.

When installing a driveway drain, a full concrete encasement is needed as drainage channels get their strength from the surrounding concrete. A minimum of 100mm is required under the channel and on both sides – this could increase if a higher load rating is needed. If pavers or an alternative surface finish is used, concrete can be poured up the sides of the channel until the depth of the finished surface.

For a typical driveway, Allproof’s domestic channel provides an ideal solution. Made from 100% recycled plastic, it is economical, durable, and easy to install and maintain.

Grate materials

Driveway channel drain grates come in a variety of material options, which cater for price points, durability, aesthetics, and manufacturing processes to provide design features such as slip resistance, heelproof and hydraulic performance.

Galvanised steel (Galv) or stainless steel grates? Allproof’s galvanised steel grates are made from mild steel, which is hot dipped to apply a protective layer of zinc. This process enables Allproof to provide an economical metal grate; however, over time the zinc layer will undergo a natural weathering process and eventually wear away exposing the mild steel. Allproof’s stainless steel grates are made from 304 or 316 grade stainless steel, which is known for its high level of resistance to corrosion. If being installed in a marine environment or close to the sea, 316 stainless steel is recommended.

Cast iron grates provide a heavy duty and robust solution for heavy wheel loads, and are only required if commercial vehicles need to access the property. However, cast iron grates are also selected for their aesthetics as they will naturally react to the environment and once oxidisation has stabilised, will have a natural dull dark brown patina, which could complement the cladding or other materials used in the vicinity.

Black plastic grates made from glass filled nylon or polypropylene do not react to the environment and will maintain their finish.

How to maintain driveway drains

It is recommended that drainage products used to protect residential property are regularly cleaned, removing any debris from the grate and channel to ensure optimum performance. Regular cleaning should be conducted monthly or at least every time the external windows and surfaces are washed down. During certain seasons, a more regular cleaning schedule may be required to remove leaves and other debris from the grates.

Every six months, the grates should be removed and any debris from inside the channel cleaned away along with any debris stored in pits and sumps that connect the channels to the main stormwater system.

Please note these timeframes may require adjusting due to the seasonal differences across Australia.