Supply chain transparency and certainty have become imperative in several industries such as food and retail, but not so much in manufacturing and construction. If resources are coming from a reliable source and they’re genuine, that’s all there is to it. Up until the last couple of years...

After two years of the pandemic, product availability is now one of the biggest concerns in the manufacturing and construction industry. Knowing where to get it, how much, and how soon concerns all parties involved in a project, from the architect to the project execution teams. It is imperative that stock from product manufacturers is available in the right place at the right time.

Supply chain uncertainty

Ever since COVID-19 wreaked havoc on global supply chains in 2019-20, it has become evident that many New Zealand sectors rely heavily on foreign suppliers for goods.

Subsequently, many suppliers to the non-residential construction and infrastructure industries have struggled to keep up with the recent changes in global trade. With transportation delays, global uncertainty and prices for a vast array of goods still rising, many companies have been forced to re-evaluate their supply chains in terms of global risk.

It is almost impossible, however, for most firms to anticipate every type of risk, and the only way to prepare for the unknown is to ensure flexibility across the supply chain. That is, being flexible enough to find alternative sources if one supplier or region is unable to supply the business. Typically, alternative sources should already be established; however, suppliers need to have the right expertise and processes in place to understand various scenarios and move quickly to adapt.

Moddex: Supply chain certainty

At Moddex, we understand the importance of a robust supply chain. Over the past decade, we’ve consistently been breaking new ground, engineering modular systems to overcome challenges across a broad range of industries and projects.

As a result of the unwavering commitment to stay at the forefront of our product category, we have diversified our supply chain to enable the continuous innovation of our product range whilst simultaneously guaranteeing that products are fully stocked.

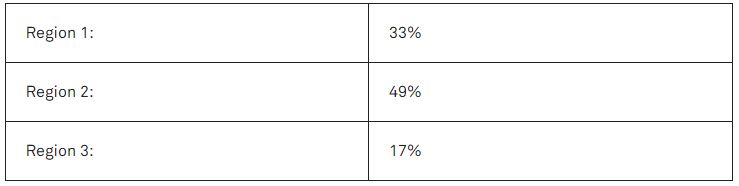

Moddex works with several suppliers globally and locally to ensure our strong in-stock position. The table below is a high-level breakdown of the percentage of product sourced locally and globally:

Components for our product ranges can be sourced from two regions at any given time and/or have an interchangeable part, should the main components be at risk in any given region. Our suppliers also keep inventory on hand in case of future supply disruptions and/or peak construction periods.

A local presence that gives you certainty

Challenges often arise on site – unforeseen modifications and variations are inevitable. Subsequently, the need for fast off-the-shelf components with predictable delivery times is a must.

All our systems are locally manufactured in New Zealand, meaning we can cost-effectively dispatch materials from our warehouse to your location in a timely manner. With Moddex, you have the confidence of knowing that our strong in-stock position ensures we can deliver what you need, when you need it.

Our extensive network of approved installers nationwide enables us to further support clients to most regional and remote locations.

For example, on the Annebrook Road project, the client used Moddex on this project because of our “readily available, cost effective product that met the required specification for the project”.

“With tight timeframes and design modifications needed, Moddex’s design team were brought onboard to assist, which was great to have a team striving to achieve a successful project outcome,” Waikato District Council said.

Trust that you are in award-winning hands

The construction industry relies on several stakeholders to keep projects moving.

Moddex won’t let you down – our mission is to make life simpler for you and give you certainty of:

- Top-quality product

- Cost-effective product

- Compliance

- Supply and parts in stock