Using XLam CLT and GLT increases site efficiency, improves sustainability, reduces capital and construction costs, enhances site safety, and improves project R.O.I.

XLAM SUPPORTS A SUSTAINABLE FUTURE.

XLam makes an important contribution to improving environmental performance of the construction industry through the manufacture and supply of sustainable building products that create “greener” buildings.

RENEWABLE PLANTATION TIMBER: XLam CLT timber stock is sourced locally from sustainably managed plantations. Our chain of custody is PEFC certified, meaning our products have been sourced from sustainable, Responsible Wood (PEFC) certified resources.

DECLARE COMPLIANT: Declare is a global environmental standard. We have met stringent standards to receive Declare Red List Free labels for both our treated and untreated panels.

LIVING FUTURE INSTITUTE: XLam CLT panels are compliant with the Living Future Institute of Australia’s Living Building Challenge.

CARBON SEQUESTRATION: Using timber as a primary building product ensures carbon sequestration. When a tree is harvested, the carbon it has sequestered during its natural life cycle is retained within its cellular structure. A timber building, in effect, locks up the carbon it has previously stored – providing a perfect environmental solution for the future.

RAPID CONSTRUCTION IMPROVES R.O.I.

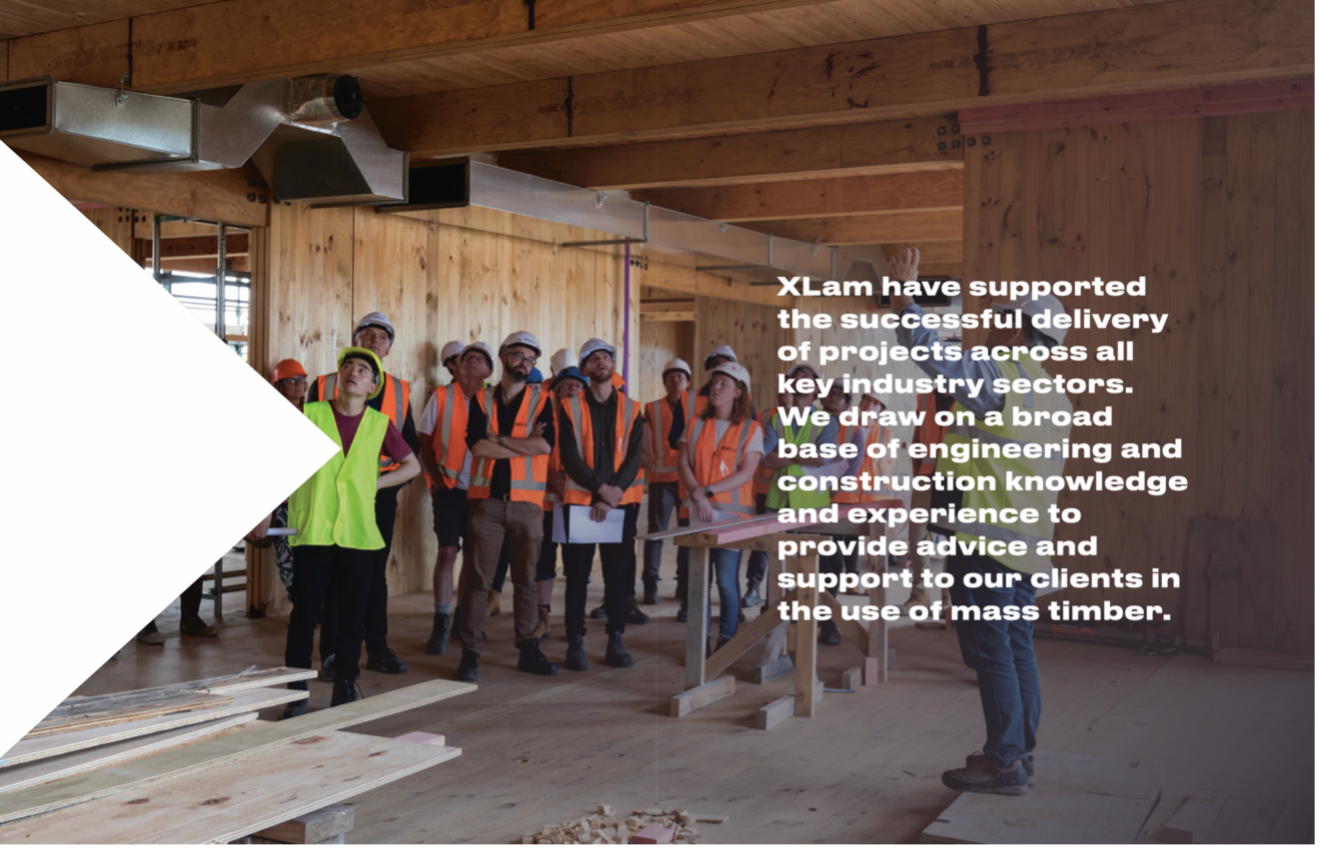

Since inception, XLam has led the market in the application of mass timber across all industry sectors in mass timber as well as in “hybrid” conventional construction. R.O.I. is improved through enhanced construction efficiency, where the use of off-site prefabricated CLT panels provide important practical benefits, as well as improved financial performance that is linked with achieving faster construction.

Improving construction efficiency and reducing the amount of time spent on site has important benefits for builders, developers and asset owners including:

• Rapid construction reducing capital and funding costs

• Higher revenue from greater turnover with the same labour resources

• Off-site manufacturing mitigates the impact of weather and protects construction schedules

• Reduction in time on site providing direct operational cost savings

• Earlier handover improving customer satisfaction and project yield

• Enhanced operating, financing, and profitability ratios

• Improved project R.O.I.

LIGHTWEIGHT AND STRONG, CLT ENHANCES BUILDING EFFICIENCY

CLT has a superior strength to weight ratio when compared to concrete or steel, offering significant advantages in weight reduction.

This allows for savings to be made on other structural elements such as slabs and frames, allows for applications such as vertical extensions on existing buildings and enables greater quantities of material on softer ground.

IMPROVING SITE SAFETY

XLam place an emphasis on health and safety across all our activities and are proud that our building products contribute to safer construction sites.

The prefabricated nature of mass timber has proven positive impacts on site safety for our customers reducing the number of processes to be performed at site, reducing headcount onsite, and providing a safe approach to achieve rapid construction while reducing risk.

XLam places an emphasis on safety, and we support our clients in the on-site application of MTC to ensure integration with their existing OH&S systems and processes.