Autex Acoustics has been a quiet force in sustainable building practices for decades, since long before "green" became a buzzword. Needing little introduction, the New Zealand-based company has long been renowned for its innovative acoustic solutions and has woven a commitment to environmental responsibility into the very fabric of its operations.

From pioneering zero-waste production lines in 1990 and innovating sustainable waste management and reuse practices – with hundreds of thousands of kilograms of waste reused each year – to achieving carbon neutrality across its entire global operation, Autex has consistently pushed the boundaries of what's possible in sustainable manufacturing. Their journey has been defined by meticulous attention to detail, an unwavering willingness to drive positive change, and a relentless focus on the future. Here, we explore some of the pivotal moments, strategies, and insights that have guided them on their way.

A step ahead of the rest

Autex's sustainability journey began well before the turn of the millennium, with the establishment of a zero-waste production line in 1990. Ahead of its time in this regard, the company recognised that making a strong commitment was essential in establishing a company culture that prioritises resource efficiency and waste reduction. Twenty years later, in 2012, Autex intensified its focus on circularity by prioritising the use of reclaimed waste trimmings and actively working to reduce raw material consumption.

However, perhaps one of the company’s most pivotal moments arrived in 2017 when Autex formed its dedicated sustainability team. While relatively uncommon at the time, this forward-thinking move marked a shift towards a more data-driven and transparent approach. Autex began meticulously measuring its greenhouse gas emissions and published its first Environmental Product Declaration (EPD), providing architects and designers with independently verified data on the environmental impact of its products, laying the groundwork for the company’s journey towards carbon neutrality. This period solidified the company’s commitment to transparency, which continues to underpin Autex's sustainability strategy to this day.

Why dematerialisation and circularity matter

With nearly 40% of global energy-related carbon emissions attributable to the building industry, the writing has long been on the decarbonisation wall (so to speak). Autex just read it sooner than others, understanding that achieving truly sustainable buildings requires a holistic approach, considering the entire life cycle of materials and prioritising those with the lowest environmental impact. This understanding has translated into innovation and action across a range of initiatives within the company.

Recognising the urgent need to reduce embodied carbon in building materials, Autex embarked on a "dematerialisation" project in 2020. Dematerialisation is a product design strategy that prioritises lower material and resource inputs across all the product’s life cycle stages while maintaining or improving the product’s overall function and performance. This ambitious initiative aimed to reduce raw material use by 30% for its core products, resulting in innovative solutions like Cube™, which delivers exceptional acoustic performance with a smaller environmental footprint.

Furthering its commitment to circularity, Autex launched a pioneering take-back program for their Acoustic Soffit Liner (ASL) in 2024. This pilot initiative, which in the future will be rolled out across the entire product range, allows customers to return used ASL products, ensuring they are properly recycled and repurposed, preventing valuable materials from ending up in landfills. This closed-loop approach exemplifies Autex's dedication to extending the life cycle of its products and minimising waste.

Sustainability, driven by innovation

One of the most significant barriers – whether it’s considered real or imagined – that many companies face in their sustainability journeys is the lack of a clear, proven path forward. For many, this brings cause for hesitation, and the translation of commitment into action stalls as a result. This has never been the case for Autex, who have taken innovation in their stride as they advance across the landscape of sustainability.

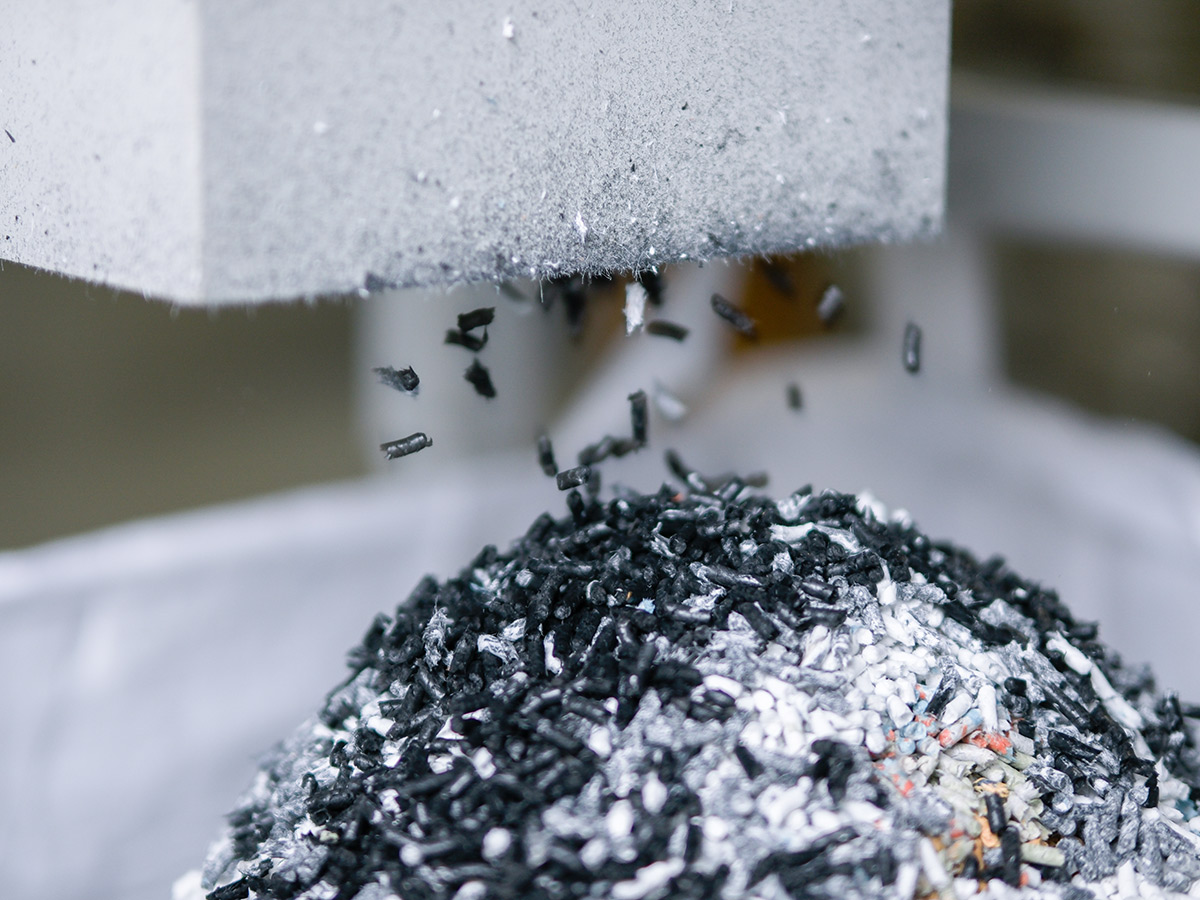

This dedication to problem-solving and experimentation has led to the development of several innovative solutions. In 2023, the company introduced a pelletising machine and process that transforms manufacturing offcuts into rigid PET pellets. Known as rePET, these pellets are a valuable resource to produce new products. This innovation not only reduces waste but also creates a new stream of recycled content for Autex's manufacturing processes.

In early 2024, Autex introduced a new product, SpinFix. Made from rePET, SpinFix offers an innovate, glueless acoustic panel installation system, simplifying installation, reducing material waste, and ensuring an easy removal and reuse of panels at the end of their life cycle. This forward-thinking approach supports the principles of "design for disassembly," enabling architects and builders to create genuinely sustainable spaces.

Carbon neutrality: a major milestone

Autex's unwavering commitment to sustainability culminated in a significant achievement: becoming the first company in the interior acoustics industry to achieve carbon neutrality across its entire acoustic product range and global operation. This milestone was reached through a combination of meticulous carbon accounting, ongoing emissions reduction efforts, and strategic carbon offsetting.

Autex's journey to carbon neutrality began with a comprehensive assessment of its carbon footprint, starting with its core manufacturing facility in 2017 and expanding to its global operations in 2019. This allowed the company to establish a baseline and identify critical areas for improvement. By implementing energy-efficient technologies, optimising processes, and investing in renewable energy sources, Autex has successfully reduced its operational emissions.

To address the remaining emissions, Autex partnered with the Evah Institute to conduct Life Cycle Assessments (LCAs) of its products, meticulously evaluating the embodied carbon from raw material extraction to the finished product. This data allows Autex to accurately calculate the carbon footprint of its products and invest in verified carbon offset projects to neutralise any remaining emissions.

Collaboration and the sustainable future of acoustics

A challenge like the one the building industry faces with sustainability cannot be surmounted alone. With great responsibility comes great collaboration, and Autex has undertaken a concerted effort to strategise and align with counterparts from all sectors of construction. The company actively engages with stakeholders, advocating for better product stewardship and promoting the adoption of circular economy principles. By sharing its knowledge and expertise, Autex hopes to inspire others to embrace sustainable practices and contribute to a greener built environment.

Every step of Autex’s journey echoes the transformative potential of long-term commitment and continuous innovation in driving sustainability. By embedding environmental responsibility into its core values, the company has not only minimised its own impact but empowered architects and designers to create spaces that are both beautiful and sustainable. As the construction industry continues to accelerate its efforts to tackle the challenges of climate change, Autex Acoustics emerges as a sound example of how – with passion, perseverance, and foresight – businesses can amplify their ambition and lead the way towards a more sustainable future.