Kaolin’s family own manufacturer, Guanxing Ceramics, continues to lead the industry in environmentally sustainable and ethical production practices with its

state-of-the-art factory, and smart warehouse, achieving the highest Environmental Certification of China.

RESPECT TO HUMAN RIGHTS AND FAIR LABOUR PRACTICE

We value the practice of fair labour. As a family business, we consider all our employees as part of the family and treat them like that. 95% of our workforce with experience of 10 years stayed with us and plans to stay. We attract talent from local area as well as from all over the country. Those values are being extended not only to our own employees, but to our partners and suppliers as well. We have practices in places to confirm and verify the fair treatment of labour in all the mines of raw materials.

As much as we try to verify the origin of materials and the practice of fair labour with respect to human rights, we also urge our customers to take that into consideration when choosing which material to supply. As a family business, we are terrified and truly disappointed to find out about horrible circumstance that labourers must work in some stone quarries, with child labour as not an exception. We do encourage our customers, to make a choice not only for sustainable and environmentally friendly products, but also to make a conscience choice with respect to other families from all over the world.

LAND USE INTENSIFICATION

Making effective use of local resources to carry out efficient production, reasonable distribution of factory zones, and optimised workmanship mean that the land area is being used to get the maximum input-output ratio, and that it meets with investment intensity, improves land allocation and utilisation efficiency, and improves the level of intensification of land utilisation.

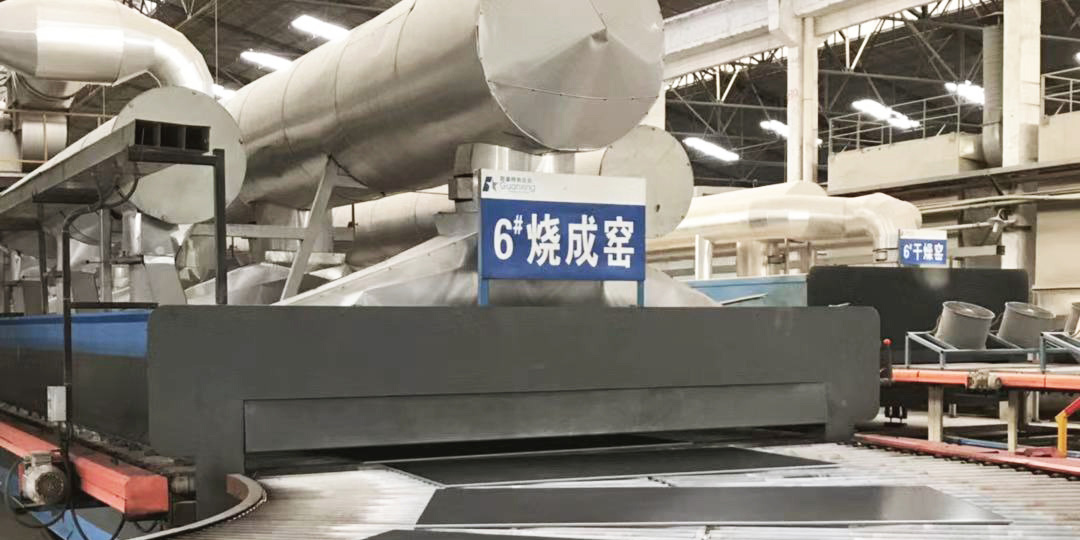

Daily production of approximately 70,000 square metres of ceramic tiles, smart factories with total investments of 300 Million AUD, occupying a space of 530,000 m2, with intelligent features and automation of production lines such as 6 lines of production per term, equipped with 10 digital HD inkjet printers, large tonnage continuous ball mills, full body material spreaders, large tonnage presses, extra-large and wide natural gas roller kilns, intelligent mechanical arms, and automated packaging machines that are in line with “Made in China 2025”.

- We work closely to get our raw materials from mines and external stockyards. Raw materials that we store at the mine or in suppliers’ stockyards are only to be shipped to the factory when needed for use, which cuts down on space taken up in the factory as well as waste.

- Raw material workshops make use of the industry’s most advanced intelligent continuous ball mills instead of traditional intermittent ball mills, which improves efficiency and at the same time, saves a lot of space.

- Packaging is conducted using intelligent automated packing lines which greatly increases efficiency and reduces the space that stacked products take up on-site. Our packaging is for almost 100% made from recycled materials and we are actively trying to minimize the amount of packaging on our product.

- Product warehouses use super-tall, three-dimensional smart warehousing which saves six times the land. For example, 36 mu [2.4 hectares] of smart warehousing can replace 200 mu [13 hectares] of ordinary flat-pack warehousing. At the same time, it greatly reduces the number of forklift trucks and warehouse staff. This form or warehousing is environmentally friendly and energy saving.

NON-HARMFUL RAW MATERIALS

The raw materials that we purchase are non-harmful. The raw materials that we purchase for the factory must have radiation levels below the national standard (≤ 0.5-1) and meet with 3C (China Compulsory Certificate) requirements. They must also be stored indoors to prevent environmental pollution following rain.

Our raw materials mostly come from mines as well as clay and sand excavated by housing developers and industrial areas. We only use environmentally friendly materials that pass radioactivity checks. Our raw materials and finished product have between 10% to 20% of Silica, which is very low compared to engineered stone (between 80% to 98%).

CLEAN PRODUCTION

Our kilns only use clean energy from natural gas which effectively reduces CO2 emissions. At the same time, we carry out dust reduction, de-sulphurisation and de-nitrification of the fume from the chimneys of the kilns. The emissions are lower than both the provincial and national standards. The gas that is emitted is completely free of smog and sharp odour. Exhaust emissions are treated with techniques such as automated high-temperature dust removal bags, intelligent SNCR de-nitration, wet de-nitration spray, and wet ionisation dust and smog removal to ensure that exhaust emissions are lower than standard limits. Automated improvements from waste water filters, independent treatment reaction systems for de-sulphurisation of wastewater, and deep sand filtration systems for recycled water ensure that recycled water meets production requirements.

- Waste water, sulphur dioxide, carbon dioxide, oxygen, and steam emitted in the production process.

- Waste water is heavy in acidic ingredients. Placing alkaline materials in the water means that it can be recycled for use in edging and polishing processes. It can also be used in slurry for ball mills.

- Particulates, sulphur dioxide, and nitrogen oxides that get released during production have been reduced to 16mg/m³, 19mg/m³, and 61mg/m³, which is more than 30% lower than national and provincial standards.

- Dust is mainly collected in dust bags. The collected dust is then re-hydrated and made into a slurry to be used in making tiles, thereby reusing it.

- Waste residue mainly comprises clay, small amounts of chemical additives, and ceramic tile shards. A filter press compresses waste residue with water so it can be put back into a ball mill and broken down for use in making tiles, thereby reusing it.

- Defective tiles and products that do not meet standards are broken down in a shredder and then put through the ball mill to be broken down and reused for making tiles.

- We offset our emission by preserving and maintaining 11.000 hectares of forest around our factory.

TURNING WASTE INTO RESOURCES

First, we reuse waste water. No industrial waste water is discharged and no waste residue leaves the factory.

Second, dangerous substances are identified, collected, and then given over to the qualified department designated by the government for safe processing.

Extended Question: What does dangerous product mean here?

Dangerous waste product mainly refers to combustible products such as empty paint pots, empty oil barrels, and soil that has been contaminated by petroleum products. Such products must be centrally collected for storage in a designated safe area and then given over to a government-designated unit qualified for the treatment of dangerous products for transportation and treatment as we cannot treat such products at our factory.

ENERGY DE-CARBONISATION

Presently, all kilns are fired using clean natural gas production, thereby achieving production with de-carbonised energy.

Guangdong Guangxing Ceramics is a model of intelligent production within the Guangdong ceramics industry. The company owns two of the industry’s most advanced fully automated continuous ball mills which saves on electricity, water, and energy. The company possesses fully automated intelligent production lines, giving full automation from the tile press down to the final processes.

The company owns the world’s second and China’s first super-tall, large-sized smart warehouse centre. Unmanned management and operation is achieved from products arriving in the warehouse to when they leave the warehouse. This effectively reduces manpower and material resources as well as further ensuring that products remain up to specs and reduces damage to products. Compared to traditional factories, smart factories save approximately more than 30% on electricity each year as well as around 30% on workers.