If you’ve ever seen switchable glass in action, you’ve probably wondered about the ‘magic’. While it’s obviously a cool and innovative piece of technology, it’s the opposite of magic. There’s a lot of complex science behind it, and creating this product requires an in-depth level of understanding. We know you might be curious about how it all works, but we’re sure you also don’t want a science lesson that’ll take all day to read, so we’ve tried to explain the whole process as simply as we can.

PLDC is key

PLDC stands for Polymer Dispersed Liquid Crystal, and it’s a film containing liquid crystal droplets that are the size of a micron. This film is the key component in making glass switchable. The sheet of film is sandwiched between two layers of glass laminate along with adhesive interlayers, all of which are then essentially cooked in a pressure oven to become a sheet of switchable glass.

What do the liquid crystal molecules do?

The liquid crystals inside the PLDC film have light-scattering properties, which is, of course, crucial in the process of transitioning from opaque to transparent and vice versa. There is essentially a matrix of droplets inside the glass that are coated in tin oxide, which enables them to conduct electricity.

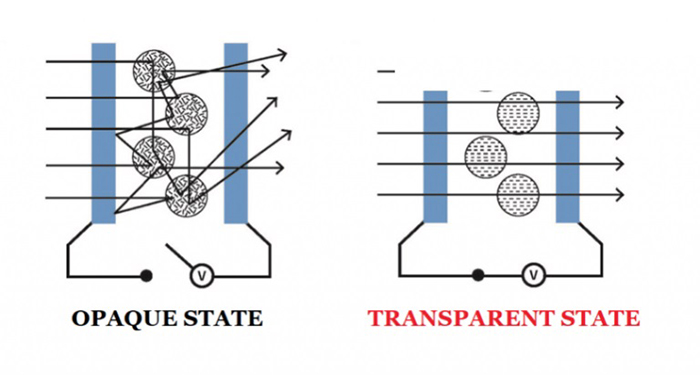

We always place electrical wires on at least two corners of each piece of switchable glass, which allows the user to inject an electrical current using a simple switch. When there is no electrical current present, the switchable glass is ‘OFF’ and in a completely opaque state. This is due to the fact that the crystal molecules are randomly oriented and group together, scattering any light.

When the user flicks the switch and turns the switchable glass ‘ON’, the electric current is allowed to flow into the crystal molecules. This causes them to line up allowing light to pass through and the glass becomes transparent.

A simple explanation

Have you ever looked at the screen of a calculator and noticed how the screen shifts depending on the light and angle? Our switchable glass uses similar technology. When physically standing very close to a window or wall made of switchable privacy glass, you’ll notice that you can see a haze within the glass from certain angles, even though it looks completely transparent when you take a step back. Despite the fact that it seems like a bit of a ‘disappearing act’ when the glass is turned ON, the molecules never actually go anywhere, they just shift.

This kind of liquid crystal technology has been around for a while, but the tricky part happens when you add glass to the equation. It takes extremely precise processes, tools and understanding to turn PLDC into Polyvision switchable glass – that’s why we have a team full of experts.

Polyvision switchable privacy glass is perfect for corporate offices, residential buildings, hotels, health facilities, and so much more.

To enquire about adding switchable glass to your organisation or including it in your next construction and design project, get in touch with one of our experts today.