In the last blog, we went over the instructions and details around how to accurately measure ceilings before SUPAWOOD panel installation. These detailed instructions and examples are to ensure installation is as seamless and easy as possible onsite, ultimately avoiding untimely delays of the project. Here, we go over how to measure walls correctly, to prevent ill-fitting panels come time for installation.

Measuring Walls

Step 1:

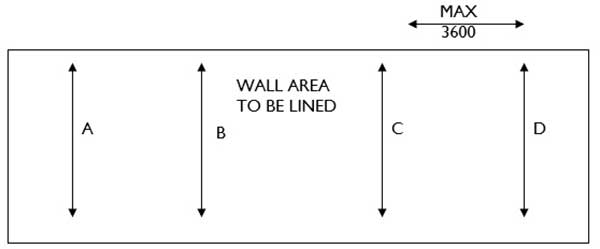

Measure height at several spots e.g., A, B, C & D maximum 3600mm apart

1.1 - If floor does not yet have final covering, deduct thickness of covering (e.g., tiles/ carpet) from height of wall.

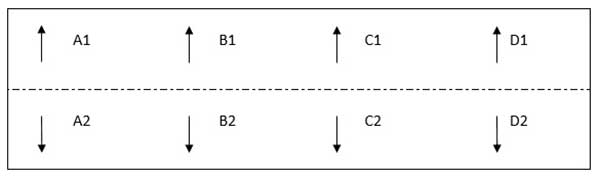

1.2 - If height measurements vary by more than 15mm:

1.2.1 - Mark a horizontal level datum line on the wall.

1.2.2 - Measure up/down from datum line.

Note: Some panels may need to be trimmed onsite if the floor or ceiling varies from level by more than 10mm.

Order panels at least 5mm longer than the maximum to make trimming easier.

Note: You can also order rectangular panels that step by 2mm at a time, which will not be obvious but will give you a consistent joint line to the floor or ceiling.

Step 2:

When Supawood panels are bordered on both sides by 90° corners to other surfaces, measure width like this:

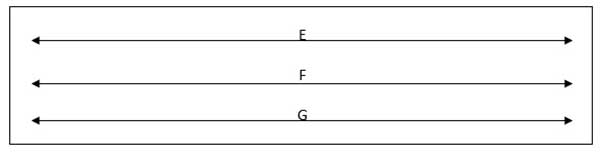

Measure width of area at top, bottom and centre, (or at 2400mm intervals if over 4m high wall) e.g., E, F & G.

2.1 - If adjoining walls do not yet have final lining, deduct (if internal corner) or add (if external corner) thickness of lining from measurement.

2.1.1 - If plasterboard, allow plasterboard thickness + 2mm for setting.

2.1.2 - If Supawood, allow for any framing still required as well as panel and battens.

2.2 - If width measurements vary by more than 8mm:

2.2.1 - Put a long spirit level against each of the adjoining walls.

2.2.2 - Identify which wall is out of plumb by more than 5mm.

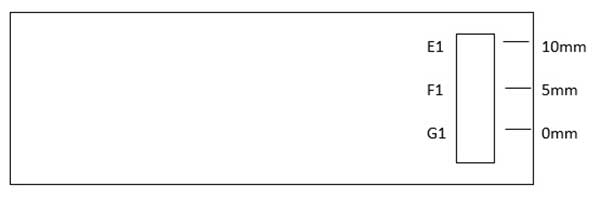

2.2.3 - Measure how much wall is out of plumb at top, bottom & middle, e.g.,

2.2.4 - Note: Some panels may need to be trimmed onsite if any adjoining surface is more than 8mm out of plumb.

2.2.5 - Sometimes the adjoining surface can be packed out/ adjusted to plumb.

Step 3:

When one or more vertical perimeters of the lined area are angled external or internal corners, or the lined area is curved or faceted, use this procedure:

3.1- Mark on floor the line of the face of the panel

3.1.1 - Allow for:

- panel

- fixing batten

- framing not yet installed

3.1.2 - A 'jig' of the required thickness can make this quicker.

3.2 - Mark on floor the finished lining face of any adjoining surfaces not yet fully lined. Allow for setting on plasterboard (2mm extra).

3.3 - Mark both edges of each panel on the floor.

3.3.1 - Use Supawood Joint Details drawings to determine exact offsets at each type of junction.

3.3.2 - Mark both sides of each express joint (where applicable).

3.3.3 - Use vertical laser to transfer overhead points to floor from ceiling if required.

3.4 - Measure each panel width on floor.

3.4.1 - Use tape measure.

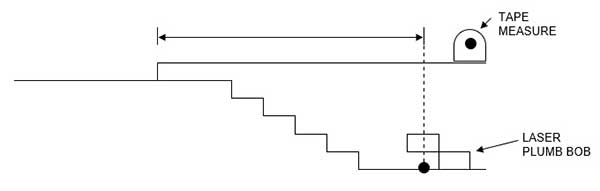

3.4.2 - Use vertical laser or similar, to measure horizontal distances down steps, or for shaped wall panels, e.g.,

3.5 - Check measure overall distance.

3.5.1 - Measure from LHS of left-hand panel to RHS of right-hand panel.

3.5.2 - Compare measurement to total of all the panels and all express joints, must be within 1mm (E10) or 1/2mm (B3)/per metre.

3.5.3 - Recheck individual panel measurements as required.

Shaped Panels

For shaped panels, refer to drawing 0702 Shaped Panel Measurements, which indicate all the measurements that Supawood requires.

Check out our last blog, where we provide step-by-step instructions on how to best measure ceilings before SUPAWOOD panel installation.

Reach out to our friendly team today to discuss any further questions about installing our products.